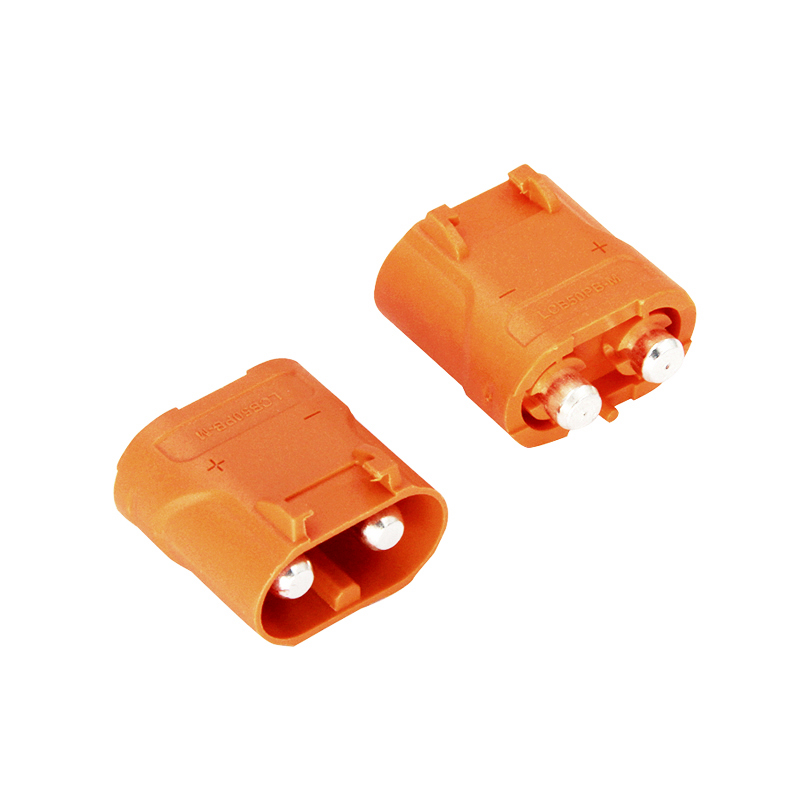

LCB50PB High current connector

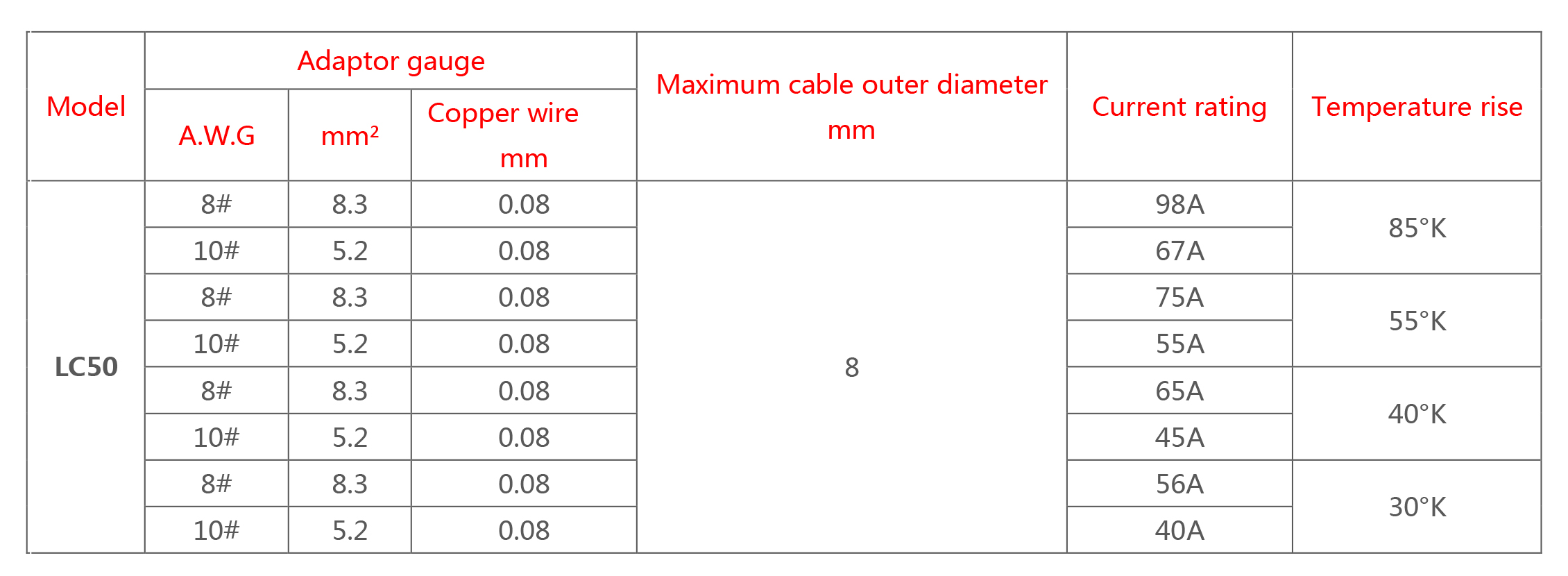

Product Parameters

Electric Current

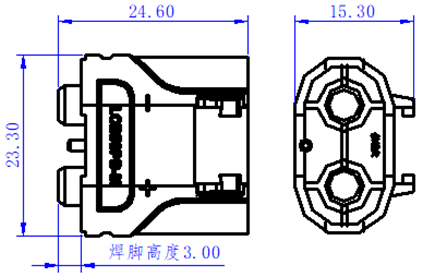

Product Drawings

Product Description

High temperature resistance of connector means that the connector can be used normally in a high temperature environment, and the material also has the required mechanical and physical properties; Amass uses PBT engineering plastics with high, low temperature and high performance that meet the needs of most intelligent devices. The melting point of the PBT insulating plastic shell is 225-235 ℃, which makes the connectors made of materials have high temperature resistance

Amass LC series lithium battery connectors have high adaptability, high reliability and other advantages in the application of solar street lamps. Due to the outdoor service conditions and regional climate, high or low temperature is also a major factor in the test of DC terminals. Extreme high and low temperatures will damage the insulation materials, reduce the insulation resistance and withstand voltage performance, and degrade or even fail the DC terminal performance. LC series DC terminals are made of high temperature resistant material PBT, which can withstand high and low temperature environments from – 20 ℃ to 120 ℃, and can adapt to the long-term continuous and stable operation of street lamps in most temperature environments

Why Choose Us

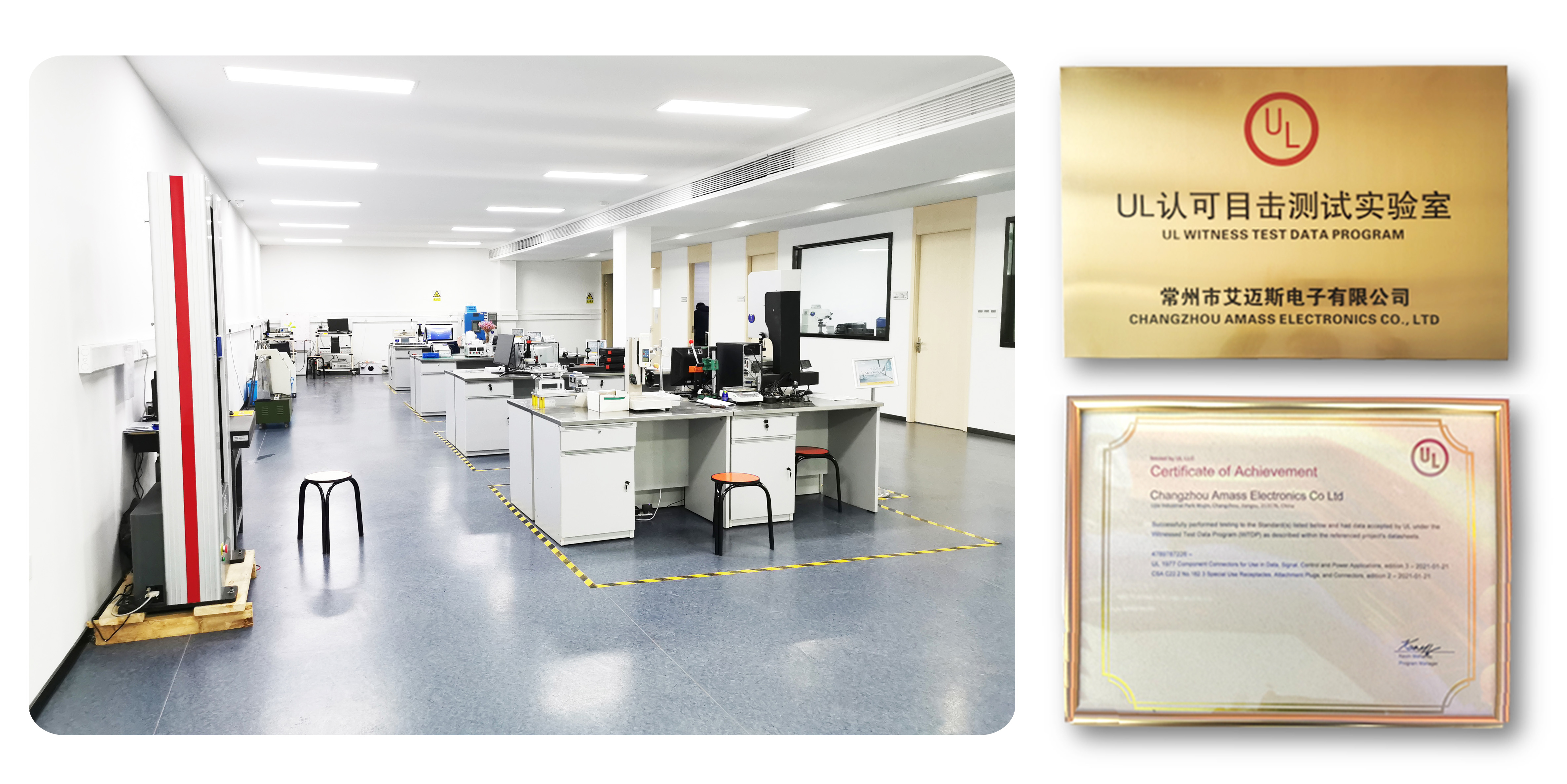

Equipment strength

Amass has current temperature rise test, welding resistance test, salt spray test, static resistance, insulation voltage

Testing equipment such as plug-in force test and fatigue test, and professional testing capabilities ensure the quality of products

Stability.

Laboratory strength

The laboratory operates based on the ISO / IEC 17025 standard, establishes four level documents, and continuously improves in the process of operation to continuously improve the laboratory management and technical capacity; And passed UL witness Laboratory Accreditation (WTDP) in January 2021

FAQ

Q: When will the goods be shipped?

A: This depends on the order quantity and requirements. It takes 3-7 days for conventional products and 25-40 days for customized products. Our daily output is 1 million pcs, so we can deliver goods in a short time.

Q: Can I customize connector products?

A: Yes, we can customize connector products according to your needs. For specific requirements and contents, please contact our sales personnel.

Q: What patents do your products have?

A: Our company has obtained more than 200 national patent certificates, including patents for inventions, utility models and designs