Are you still looking for high-performance and cost-effective internal connectors for consumer-grade smart devices, Amass fourth-generation products XLB30 and XLB40 will satisfy your needs! As the upgraded models of XT, XLB30 and XLB40 have doubled the performance and are more favorable in price, which can be widely used in the fields of energy storage devices, garden tools, electric vehicles, intelligent robots, intelligent small home appliances, and drones. Now XLB30 and XLB40 have been newly launched, if you are interested in them, why don’t you take a deeper look?

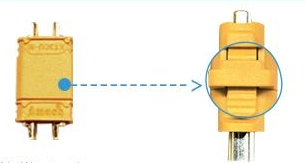

Newly Added Side Wing Snap Anti-Shock and Defense Shedding Has The Safeguard

During the operation of mobile smart devices, vibration and harness pulling are common phenomena. XT connectors are prone to loosening due to the lack of snap-on design. In contrast, XLB30 and XLB40 have upgraded the Side Wing Snap design, which ensures that the pull-off force of XLB30 is ≥6kgf and that of XLB40 is ≥8kgf, which effectively eliminates the potential danger of loosening of the pairs of pairs of plugs caused by high-frequency vibration and strong pulling, and meets the standard of GB/T 26846 on the connector’s pull-off force.

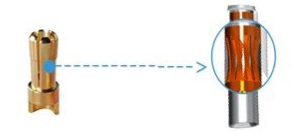

Crown Spring Structure Insertion Stabilization Anti-Shock Long Life

XT cross slot structure of the product, in the long-term high-frequency vibration under the contact force of the contacts will continue to decay significantly. Compared with XT, XLB30 and XLB40 adopt more reliable crown-spring contact structure, and the slotted main bar is upgraded to 12 contacts, which can effectively solve the problem of collapsing cross slot of XT inclined insertion, and have a long service life under high-frequency vibration.

B-type Riveting Process Eliminate Cold Soldering Control Stabilization

Compared with the welding process adopted by XT, XLB30 and XLB40 adopt a more reliable B-type riveting process, which can effectively eliminate false and empty welds, thus improving connection stability. Quality control is effectively guaranteed by monitoring the testing of key indicators such as pressure height, compression ratio and pull-off force. At the same time, the use of common equipment and conventional operation process in the industry makes it more convenient to use.

Lead-free Environmental Protection Authoritative Certification Export Worry-free

XT’s environmental standards cannot meet international export requirements, which can easily affect product sales. The XLB30 and XLB40 connectors, on the other hand, comply with the three major international environmental regulations of ROHS2.0, REACH, and California 65, which makes your products trade without barriers.

200% Increase In Anti-reverse Insertion Ability Higher Security

When inserting XT products, the production line staff sometimes encounters reverse insertion of positive and negative poles, which leads to operational errors. In order to solve this problem, the material of the plastic shell of XLB30 and XLB40 is upgraded to PBT, which significantly improves the structural strength; the reverse insertion force is upgraded from 3kg for XT series to 10kg for XL series, which effectively strengthens the anti-reverse insertion ability and durability of the products, and reduces the rate of errors in the production process.

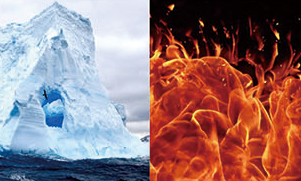

Made Of Engineering Plastic PBT For Durability

Compared with the XT PA6 material, its long-term operating temperature range is -20 ~ 100 ℃; while the XLB30, XLB40 adopts the PBT plastic shell material, its long-term operating temperature range is raised to -40 ~ 140 ℃, and it can continue to work stably under the extreme temperature environment, which improves the environmental adaptability of the product.

Comply With The New National Standard Of Flame Retardant GB 42296-2022 For Electric Vehicles

The new national standard for electric vehicles references GB/T5169.11-2017 Electric and Electronic Products Fire Hazard Experiment Part 11, which was formally implemented on 2023-7-1.The scorching wire test temperature of PA6 material used in XT is 750°C, while the scorching wire test temperature of PBT material used in XLB30 and XLB40 is 850°C, which is a 13% enhancement of the capacity, and the safety is more guaranteed.

PCB Mounting Application Without Obstacles

XLB30, XLB40 and PCB surface drop ≥ 1.6mm, the center distance and the size of the soldering feet and XT to maintain consistency, increase the positioning holes to prevent dorking, the snap parts drop design will not affect the board end layout, to ensure that the installation process smooth and unimpeded.

Upgraded accessories Optional back cover for safety and aesthetics

XLB30 and XLB40 are developed with matching back covers to meet your diverse needs. You can personalize the matching and freely choose to use the back cover/sleeve of heat shrink tubing for insulation protection.

The XLB30 and XLB40 are Amass’ carefully developed 2PIN consumer-grade smart device internals, which are highly recommended in terms of both excellent performance and cost-effectiveness.

Post time: Mar-30-2024