Connector is a huge and diversified component. Each connector type and category is defined by shape factors, materials, functions and special functions, which make them uniquely suitable for the application they are designed for.

As we all know, the connector is composed of contact, shell, coating and other parts. Among them, the contact is the core component of the connector to complete the electrical connection function of intelligent equipment. The contact structure will directly affect the service life and electrical parameters of connector products and complete equipment.

The contact spring provides a path for the transmission of signals, power and / or ground between the circuits to which the connector is connected. It also provides the normal force, that is, the component of the force perpendicular to the contact surface, which helps to form and maintain the separable interface.

Next, Amass will take you to know what structures amass connector contacts have and what are their advantages?

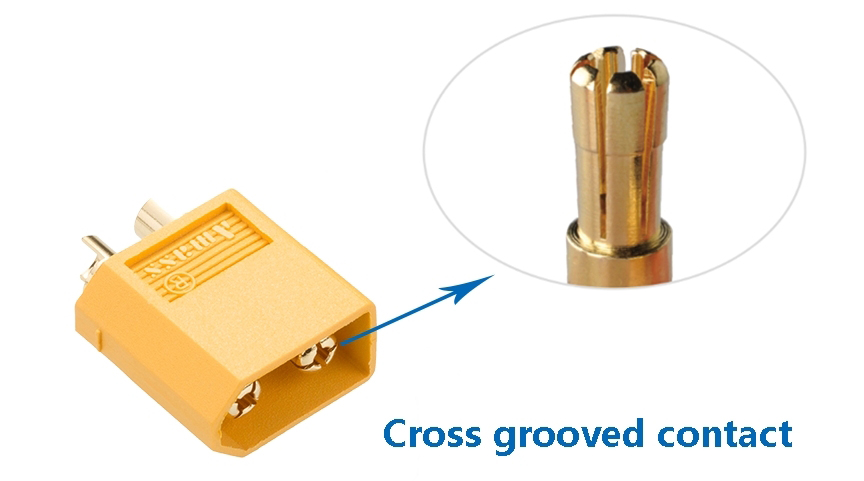

1. Cross grooving

Cross slotting is the connector contact structure commonly used in amass connectors. The cross slotting structure is conducive to the internal heat dissipation of the connector and prevents the internal pressure from being too large, resulting in the failure of the connector.

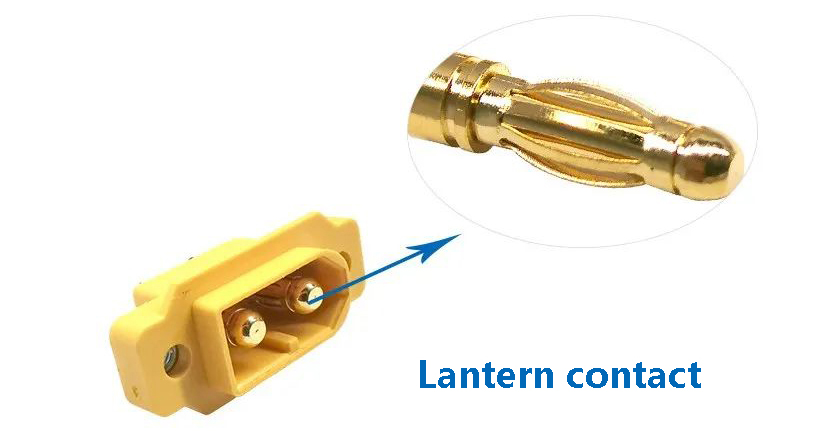

2. Lantern structure

The connector with lanterns structure is suitable for high-frequency vibration application scenarios, such as electric chain saws, branch shredders and other strong vibration scenarios. Resistant to repeated plugging, effectively extending the service life of intelligent devices; Moreover, the lantern structure can prevent the copper parts from closing during the manual assembly of the cross slotted contact parts.

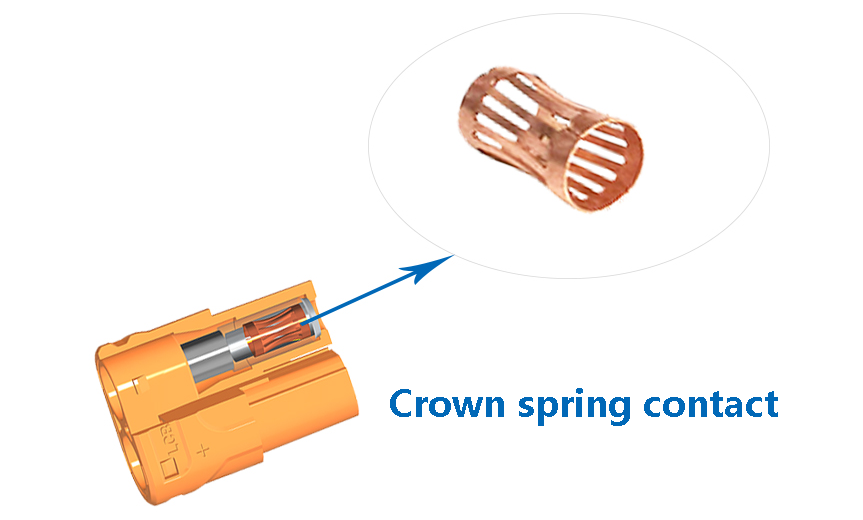

3. Crown spring structure

The crown spring structure contact is mainly used in the LC series of Ames' fourth generation lithium battery connectors. The 360 ° crown spring contact structure can not only increase the plug-in life of the connector products, but also effectively prevent its instantaneous disconnection during the plug-in process; The contact of crown spring structure adopts red copper conductor, which greatly improves the current carrying performance compared with brass conductor.

Post time: Aug-17-2022