Connectors are components of electronic equipment that play a role in connection, and the insertion and extraction force refers to the force that needs to be applied when the connector is inserted and pulled out. The size of the insertion and extraction force directly affects the performance and reliability of the connector. Appropriate insertion and extraction force can ensure that the connector in the normal use of the process of solid and reliable connection, so as to avoid signal loss or transmission interruption and other issues.

The insertion and extraction force of a connector is determined by a number of factors such as connector design, material and processing technology. If the insertion and extraction force is too large, the connector may be damaged or unable to stabilize the connection; if the insertion and extraction force is too small, it is easy to disconnect or loosen the situation. Therefore, the plugging and unplugging force of the connector is an important indicator to ensure the normal operation of the connector. Connector design needs to take into account the balance of insertion and removal force, not only to ensure that the connector is firm and stable, but also to facilitate the user to carry out insertion and removal operations.

The insertion and extraction force of a connector is divided into insertion force and pull-out force (pull-out force is also called separation force), and the requirements of the two are different.

From a usage perspective

Insertion force should be small, and separation force requirements to be larger, once the separation force is too small, it will be easy to fall off, affecting the reliability of the connector contact. But the separation force is too large will lead to pull out the difficulty, personnel operation time-consuming and laborious, for the insertion and extraction of too many times or the need for frequent maintenance of the equipment will increase a lot of trouble.

From the degree of product reliability

Insertion force should not be too small, too small insertion force is easy to fall off, resulting in the use of equipment in the process of loosening the poor contact and so on.

So what kind of connector insertion and extraction force can ensure the reliability of the product as well as user-friendly operation?

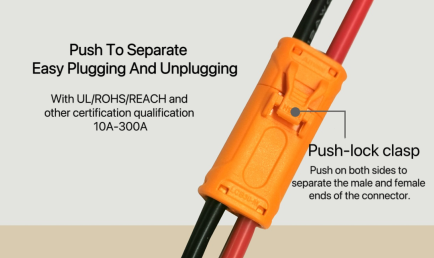

Amass LC series smart device connector can be pulled out without too much insertion and withdrawal force, the main reason is from the hidden buckle design. Press and push the buckle to separate the connector, the unique buckle design not only ensures the fit of the connector when inserted, but also keeps the user effortless to pull out, avoid the occurrence of loose and poor contact in the vibration environment, effectively ensure the normal use of the connector function!

About Amass

Founded in 2002, Amass Electronics (the original XT series) is a national specialized and special new “small giant” enterprise and provincial high-tech enterprise integrating design, R&D, manufacturing and sales. Focusing on lithium high-current connectors for 22 years, we are deeply engaged in the field of small power intelligent devices below the automotive level.

Up to now, we have more than 200 national patent certificates, and have obtained RoHS/REACH/CE/UL qualification certificates, etc.; we continuously contribute high-quality connector products to various industries, and help the project operation of the whole life cycle to be easy and hassle-free. Accompanying customers to grow together, reduce costs and increase efficiency, collaborative innovation!

Post time: Dec-02-2023