The connector is a very important connection component inside the smart device, and people who often contact the connector know that the connector contact will be plated with a metal layer on the original metal material. So what is the meaning of the connector coating? The plating of the connector is closely related to its application environment, electrical performance and other factors.

The plating can not only effectively reduce the corrosion of the environment on the connector, improve the durability and corrosion resistance of the connector, but also help establish and adhere to the stable connector impedance from the electrical function. Specific performance is as follows:

The plating improves the corrosion resistance of the connector

Intelligent equipment used outdoors is often prone to rust and oxidation due to environmental uncertainties such as rain, wind, snow, and dust storms; Therefore, the first consideration of the internal connector is corrosion resistance, and the corrosion resistance of the connector can be improved in addition to its own material, and the plating can also be improved.

Most connector contacts are made of copper alloy, and copper alloy because of its alloy composition is more susceptible to corrosion in the working environment, such as oxidation and vulcanization. The coating prevents contact with corrosive components in the application environment and prevents copper corrosion.

The Amass XT series connector copper parts are made of brass plated with real gold, and the metal activity of “gold” is relatively backward, thus greatly increasing the corrosion resistance of the connector in the application environment.

The plating helps to improve the mechanical properties of the connector

As far as the connection function of the connector is concerned, the insertion and withdrawal force is an important mechanical property. Another important mechanical property is the mechanical life of the connector. The choice of coating will affect these two points, in the connector that is often inserted, the coating needs to have a certain wear resistance, if the coating is missing this characteristic, it will affect the fit of the connector, thus affecting the service life of the connector.

The plating helps to improve the electrical performance of the connector

A major requirement for the electrical performance of connectors is to establish and maintain a stable connector impedance. For this purpose, metal contacts are required to provide such inherent stability. This stability can be provided in addition to its own contact parts, the coating can also be provided, the coating has high electrical conductivity, and the electrical performance of the connector is more stable.

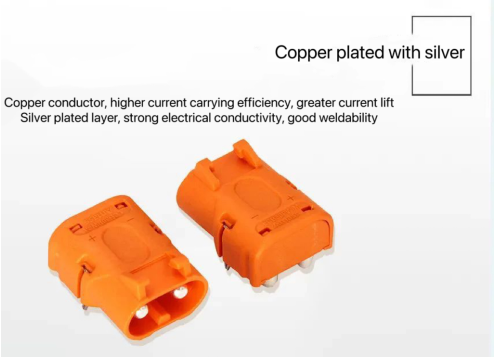

Amass LC series connectors use copper conductor, copper is a relatively pure kind of copper, generally can be approximately considered to be pure copper, electrical conductivity, plasticity are better. Copper has excellent thermal conductivity, ductility and corrosion resistance. Compared with other copper alloys, the electrical conductivity is strong and the resistance value is low, and the surface layer is a silver-plated layer with higher electrical conductivity than copper, which greatly improves the electrical performance of the connector.

Post time: Aug-26-2023